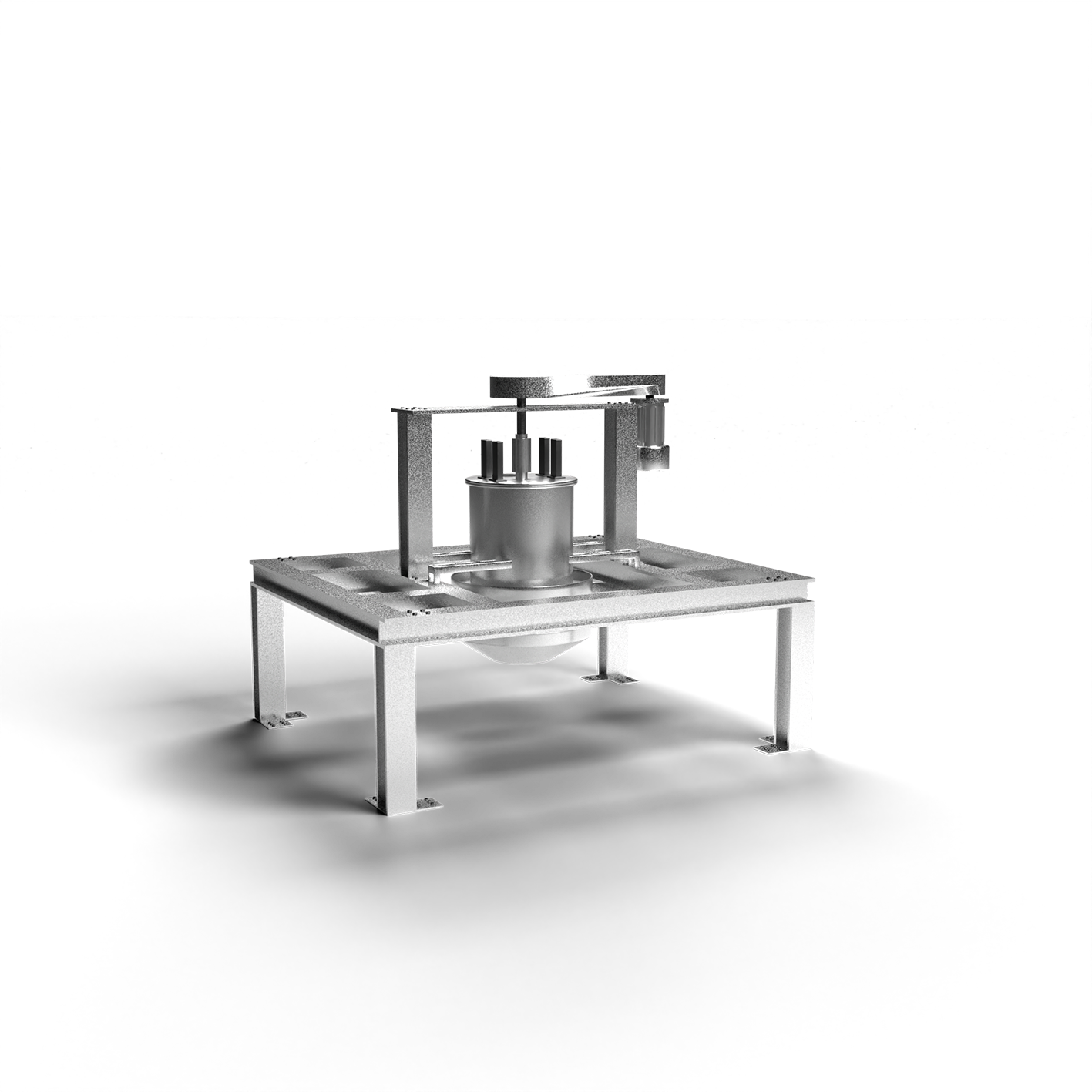

ELECTRIC MOTOR AND MILLING SYSTEM

The Tritor Hurricane® is powered by an electric motor rated between 45 kW and 55 kW, generating substantial centrifugal force that activates the fragmentation system within the grinding chamber.

This motor drives a system of spherical bodies (balls or hammers) that rotate, crushing incoming material into fragments suitable for subsequent treatments.

GRINDING CHAMBER

The core of the system is the grinding chamber, internally lined with removable Hardox 450-500 strips, a steel highly resistant to impact and gentle on friction. These strips are designed to reduce chamber wear and enhance process efficiency.

VANES AND BALLS: PULVERISATION OPTIMISATION

The vanes, rotating components on the shaft, are also constructed from Hardox 400 and, together with the balls, maximise pulverisation efficiency. The geometric configuration of the vanes is designed to optimise the movement of crushing bodies, reducing component wear and increasing the machine’s volumetric reduction capability.

BLADES ON THE ROTATING PLATE

Blades on the rotating plate further reduce the transverse particle size of the processed material. With an adjustable orifice height between 2 and 5 mm, the output material can be processed to reach very small sizes, ensuring readiness for subsequent processing or recycling stages.

Pictures and technical specifications provided by the manufacturer.