Greater efficiency, lower consumption: waste valorisation at its best

Greater efficiency, lower consumption: waste valorisation at its best

REDUCING WASTE VOLUMES:

A CORE STEP TOWARDS SUSTAINABILITY

Volume reduction of waste is a crucial step in advancing towards a sustainable circular economy. Compressing waste and minimising its mass and volume are essential pre-treatment processes before materials can undergo recycling or repurposing.

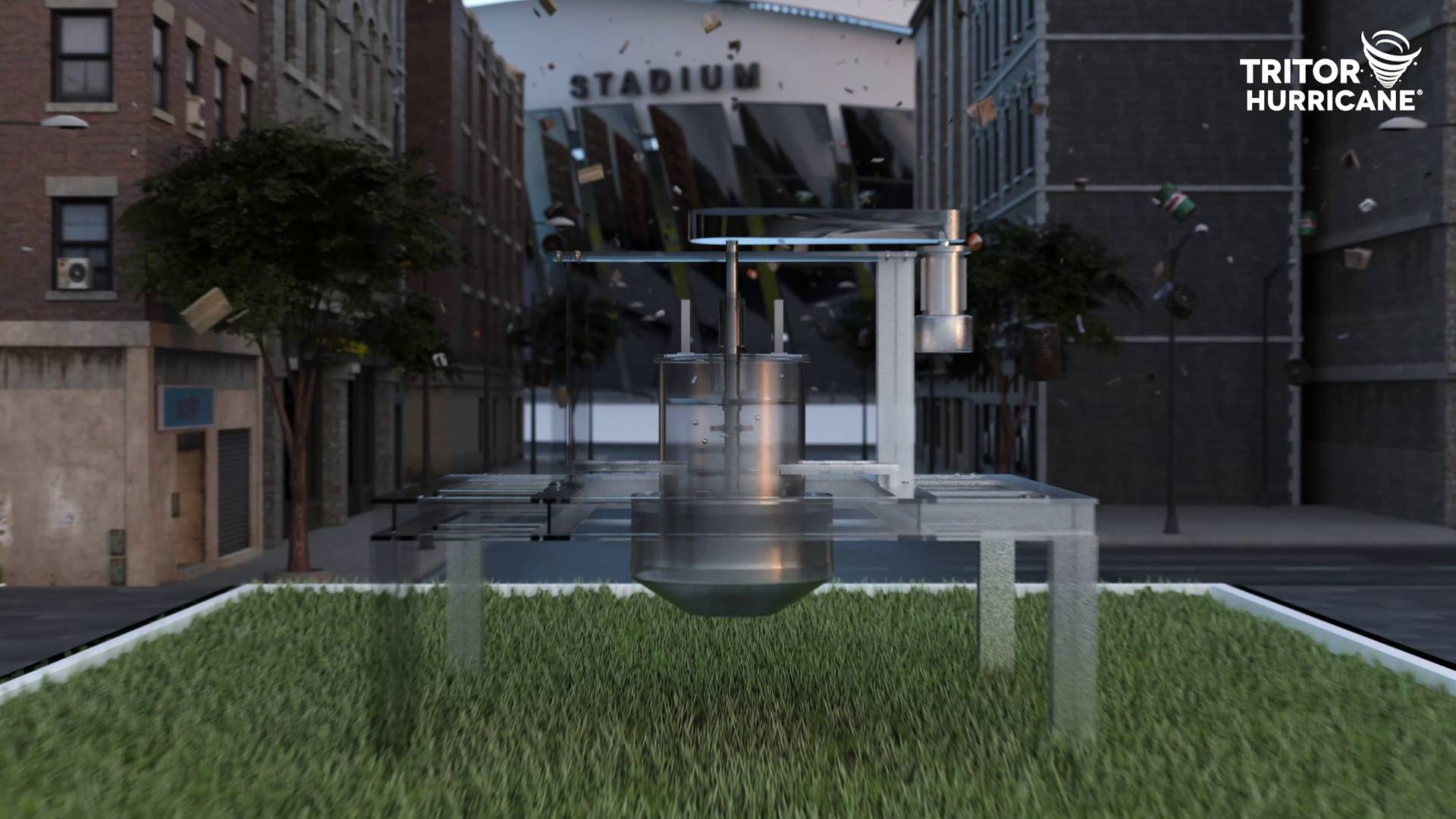

The Tritor Hurricane® is engineered as a breakthrough in “pulverization” technology, aiming to significantly reduce energy costs compared to existing solutions while enhancing the effectiveness of volumetric and mass reduction.

The Tritor Hurricane® is an innovative plant designed for pulverising and dehydrating waste via a system that harnesses centrifugal force and an integrated hot air vortex. This design enhances efficiency while reducing energy consumption.

Its compact structure and advanced features make it one of the most efficient and sustainable plants available on the market.

Additionally, the introduction of hot air allows uniform heating of the entire grinding chamber.

HEATING SYSTEM AND ENERGY SAVINGS

A standout innovation in the Tritor Hurricane® is its ability to dehydrate by heating with a hot air vortex, eliminating additional electric consumption. This novel system achieves higher temperatures within the grinding chamber with lower energy consumption.

The combination of hot air and the milling system’s movement creates a vortex that increases material dehumidification capacity, optimising the process and further reducing energy consumption.

SUPERIOR ENERGY EFFICIENCY AND PERFORMANCE

Despite its relatively low motor power (45 kW), the Tritor Hurricane® delivers performance equivalent to that of machines with far more powerful motors, thanks to optimised design and transmission systems.

The machine’s high Coefficient of Performance (COP) between electric energy input and pulverised mass output is a key factor distinguishing it from competitors, ensuring a substantial reduction in operational costs.

MONITORING AND AUTOMATION VIA PLC

The Tritor Hurricane® is equipped with an advanced monitoring system based on a Programmable Logic Controller (PLC), enabling real-time control of machine operating parameters. The system monitors the moisture content and specific weight of incoming and outgoing material, ensuring optimal pulverisation management.